Does HIP affect the dimensional accuracy of the part during densification?

Does HIP Affect the Dimensional Accuracy of the Part During Densification?

Overview

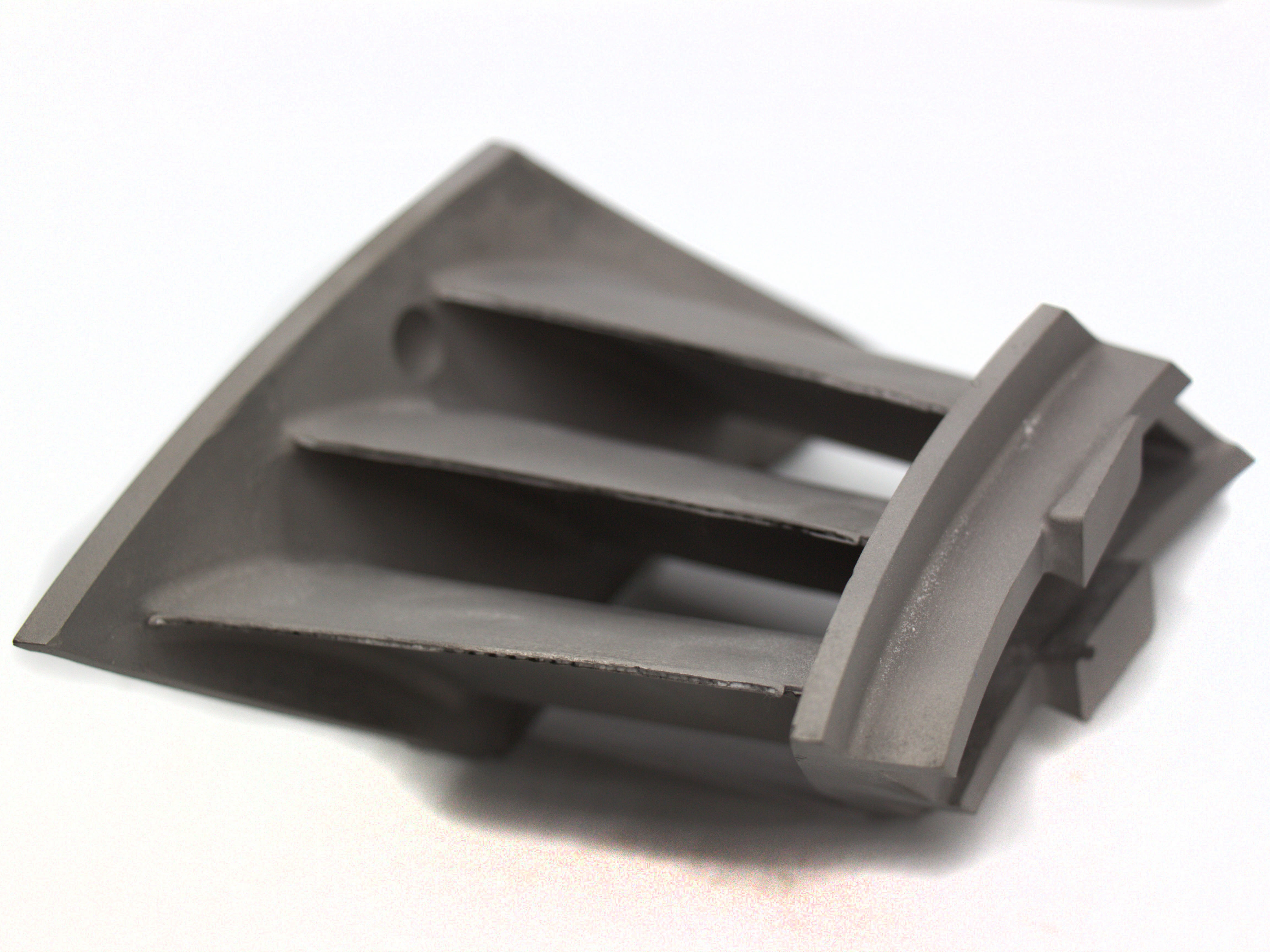

Hot Isostatic Pressing (HIP) improves the density and mechanical properties of 3D printed metal parts by applying high temperature (900–1250°C) and isostatic gas pressure (100–200 MPa). While HIP effectively eliminates internal porosity, it can cause slight dimensional changes due to material consolidation. Understanding and managing these changes is essential for achieving final part tolerances in high-precision applications.

How HIP Impacts Dimensional Accuracy

1. Shrinkage Due to Porosity Collapse

During HIP, internal microvoids collapse as material diffuses and flows to fill gaps. This densification can result in:

Isotropic shrinkage of approximately 0.1% to 0.4%

More pronounced shrinkage in parts with high initial porosity

Uniform shrinkage in all directions (X, Y, Z axes)

For example:

Ti-6Al-4V: typical linear shrinkage ~0.15–0.2%

Inconel 718: ~0.1–0.3% depending on porosity and build density

2. Geometric Deformation in Thin or Unsupported Sections

Non-uniform wall thicknesses, internal channels, and unsupported features may deform slightly due to localized stress redistribution during HIP. Without proper design support or fixturing, this may affect:

Flatness or straightness in long or thin geometries

Internal hole diameters and concentricity

3. Surface Texture and Finish

Surface dimensions remain largely unchanged, but oxidation or scale formation can occur if the part is not encapsulated or processed in a controlled atmosphere. This may require secondary post-processing like:

Strategies to Maintain Dimensional Accuracy

Compensate for shrinkage during design (oversize model by 0.1–0.4%)

Use encapsulation (canisters) for thin-walled or complex components to prevent deformation

Apply finishing operations post-HIP to restore tight tolerances

Applications Where HIP Accuracy Matters

Medical implants in Ti-6Al-4V ELI

Sealing surfaces and threads in SUS630/17-4 PH

Precision turbine rings and nozzles in Haynes 230

Recommended Services for Dimensional Control

Neway 3DP offers an integrated HIP workflow supported by:

Hot Isostatic Pressing For densification and performance reliability

CNC Machining For post-HIP dimensional correction and finishing

Heat Treatment To stabilize geometry after HIP or prepare for final machining