Can HIP effectively smooth internal surfaces or complex geometries?

Can HIP Effectively Smooth Internal Surfaces or Complex Geometries?

Internal Densification Without Mechanical Contact

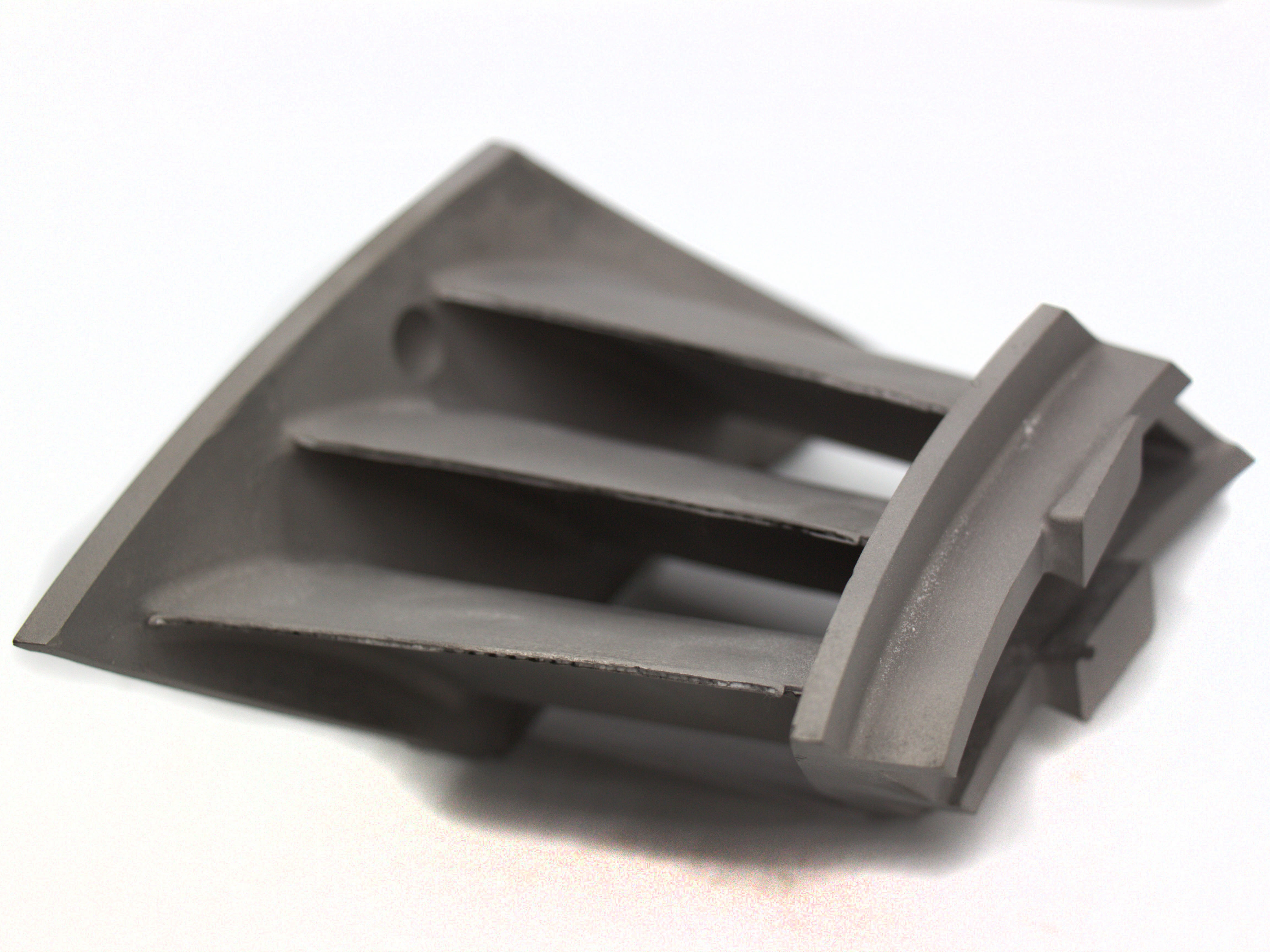

Hot Isostatic Pressing (HIP) is highly effective at enhancing the internal integrity of 3D printed parts, including those with complex geometries and internal channels. It applies uniform isostatic pressure and elevated temperatures (typically 100–200 MPa at 900–1200°C) in an inert gas environment to eliminate internal porosity. Because HIP acts through gas pressure rather than mechanical tooling, it can reach and consolidate material within intricate structures where conventional methods, such as grinding or polishing, are inaccessible.

Unlike machining or blasting, HIP does not “smooth” surfaces in the traditional sense. Instead, it reduces subsurface voids and shrinkage porosity, improving material continuity across thin-walled or internally complex features often produced in Powder Bed Fusion or Directed Energy Deposition processes.

Surface Roughness vs. Internal Quality

While HIP improves subsurface homogeneity and fatigue resistance, it does not significantly alter surface roughness (Ra) values. Typical as-printed internal surface roughness in DMLS or SLM parts remains in the Ra 6–12 µm range post-HIP. Internal surface topology—especially in curved or lattice structures—remains largely unchanged unless followed by internal-specific treatments like chemical polishing or abrasive flow machining (AFM), which are often used for internal flow optimization.

Best-Use Cases for Internal HIP Enhancement

HIP is particularly suited for:

Lattice and gyroid structures in aerospace or energy cooling systems.

Internal passageways in titanium heat exchangers or conformal-cooled molds.

Sealed voids in superalloy or stainless steel turbine components require uniform mechanical properties.

By increasing fatigue strength and minimizing internal crack initiation sites, HIP contributes to long-term reliability and performance in components where internal geometry is functionally critical.

Recommended Services for Internal Surface and Structural Enhancement

For optimal performance of parts with internal complexity, Neway recommends the following service combination:

Complex Part Fabrication Services:

Titanium 3D Printing: For thin-walled, biocompatible, and heat-resistant internal structures.

Superalloy 3D Printing: Ideal for structural parts in turbines and exhaust systems.

Post-Processing for Internal Integrity:

Hot Isostatic Pressing (HIP): Removes internal porosity in complex geometries.

Heat Treatment: Adjusts internal stress profiles for better fatigue resistance.

Optional Internal Surface Refinement:

Electropolishing: For accessible internal areas in metallic parts.

CNC Machining: For accessible cross-sections or intersecting ports requiring precision tolerances.